What is an Impeller?

Impeller is a mechanical device which is used to move a fluid or air to an intended direction at an angle to the incoming source. An impeller is opposite to turbine which increases fluid pressure and flow of fluid while on the other hand a turbine extracts energy from the fluid by reducing its pressure. Impeller is often housed into a confined ducted space (termed as pump housing) which allows the fluid to be funneled to a particular direction.

Impellers Designs

Here we will take a look at two types of impeller designs;

- Impeller Design - Centrifugal

- Impeller Design - Axial

Impeller Design - Centrifugal

Airfoil

Airfoil has the highest efficiency and low noise among the centrifugal impeller designs with 9 to 16 blades of airfoil outline curved away from the direction of the rotation. The fluid leaves the impeller at a velocity less than its tip speed. As fluid approaches the blade’s leading edge, the stream splits and travels above and below the blade. The fluid is deflected across the convex curve along the top of the blade and along the flat or concave curve on the bottom of the blade, and flows downward over the sharp trailing edge as it leaves the blade.

Airfoil Applications

Primary application includes

- General HVAC Systems

- Industrial Applications as Clean Air Provider

Backward Inclined or Backward Curved

This is slightly less efficient design than airfoil, backward curved impeller generally has lower number of longer blades curved away from the direction of rotation and curved backward from inner edge to outer edge relative to the direction of rotation.

Backward Inclined or Backward Curved Applications

Primary application includes

- General HVAC Systems

- Industrial Applications where airfoil is not recommended due to corrosive environment.

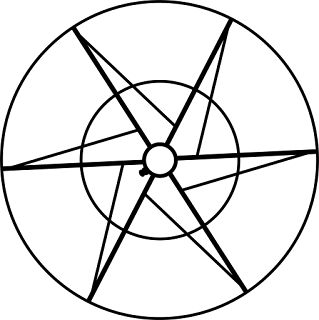

Radial

Radial impeller design is at which fluid leaves the impeller in all directions perpendicular to shaft. Radial impeller is the simplest and least efficient design and has high mechanical strength and can be easily repaired.

Radial Applications

Primary application includes

- High pressure requirements

- Simultaneous solids suspension mixing in low-to-medium-viscosity liquids

- Low shear applications in which fluid movement helps promote solid suspension

Forward Curved

Forward curved impeller designs are less efficient than airfoil and backward curved impellers. A forward curved impeller is characterized by a relatively large number of shallow blades facing the direction of rotation. For this type of impeller, flow from the impeller is produced in a tangential direction.

Forward Curved Applications

Primary application includes

- Low pressure HVAC systems such as domestic furnaces, central station and package type units

Impeller Design - Axial

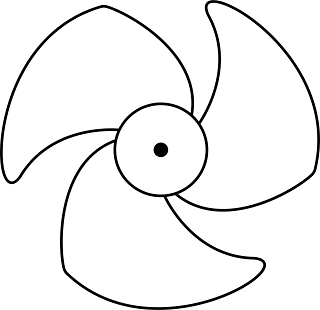

Propeller

It has low efficiency and usually limited to low pressure applications. It has usually two or more blades of uniform thickness attached to a relatively small hub. Energy is transferred in the form of velocity pressure.

Propeller Applications

Primary application includes

- Low pressure, high volume air moving applications such as ventilating a space.

- Used in industrial ventilation

Tube Axial

Tube axial design is slightly more efficient than propeller design and is capable of developing more useful static pressure ranges. Generally it has 4 to 8 blades connected to a hub normally diameter less than the 50% that of fan tip diameter. Blades can be of uniform thickness or airfoil cross section.

Propeller Applications

Primary application includes

- Low to medium pressure ducted HVAC applications.

- Industrial applications such as drying ovens, spray paint booths and fumes exhaust systems.

Vane Axial

Its a tube axial fab with with air guide vanes located before or after the impeller. The air guide vanes improve the efficiency of the axial fan when discharging against the pressure. Blades are fixed to adjustable pitch type and the hub is usually greater then 50% of the fan tip diameter.

Vane Axial Applications

Primary application includes

- General HVAC systems in low to medium and high pressure applications.

- Basement ventilation and exhaust systems.

- Applications where straight flow and compact installation is required.

- Industrial applications such as dry ovens, spray paint booths etc.

0 Comments

Please avoid posting spam links in the comment section.