What is Compressor?

Reciprocating Air Compressor

The term

Reciprocating

refers to the back-and-forth

movement of the compression device (a piston or other

device is positioned in a cylinder).

Reciprocating compressors

use the inward stroke of a piston to draw (intake) gas into a

chamber and then use an outward stroke to positively displace (discharge) the

gas. A common application for the reciprocating compressor is in an instrument

air system.

This is the most commonly used type and is

very versatile. It uses a piston and cylinder design to compress the

refrigerant. Powered by a motor and crankshaft, the piston moves up and down

inside the cylinder. The refrigerant is sucked into the cylinder by a vacuum

that is created as the piston moves down. When the piston moves back up, it

compresses the gas, which is then pushed into the condenser. Reciprocating

compressors are very efficient and you can get AC units that have 2, 4, or even

8 cylinders in its compressor.

Scroll Air Compressor

Scroll air conditioning compressors, are newer on the

scene. They contain one fixed coil-called the scroll-in the center of the unit,

and then there is another coil that rotates around it. During this process, the

second scroll pushes the refrigerant towards the center and compresses it.

Scroll compressors are quickly becoming as popular as reciprocating compressors

because they do not have as many moving parts and are therefore more reliable.

The advantage of scroll compressor is that it has fewer moving parts and

less torque variation compared to the reciprocating compressor. This advantage

is translated to a smooth and quiet operation. The scroll compressor is also known as scroll pump or scroll vacuum pump.

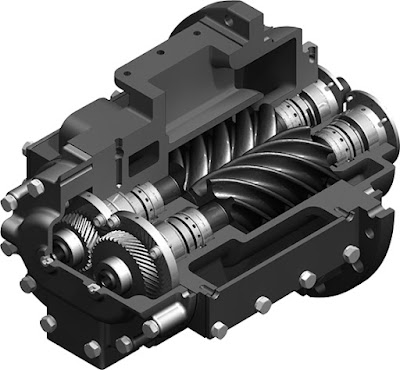

Screw Air Compressor

The screw compressor is extremely reliable and efficient,

but it is mainly used in large buildings where there is a vast amount of air

that requires continuous cooling. A screw air conditioning compressor contains

two large helical rotors that move the air from one end to the other. As the

refrigerant moves through the compressor, the space gets smaller, and it gets

compressed.

Rotary Air Compressor

Centrifugal Air Compressor

The final type of AC compressor is the centrifugal

compressor. As the name implies, it uses centrifugal force to pull in the

refrigerant gas and then spins it rapidly with an impeller to compress it.

Centrifugal air conditioning compressors are usually reserved for extra-large

HVAC systems.

Now that you know the different types of air conditioning

compressors, you can choose the one that you think will serve your needs the

best in terms of reliability and efficiency.

0 Comments

Please avoid posting spam links in the comment section.